This edition of Sustana Fiber’s ‘Conversations with Green Champions’ is with Barak Bright, Director of Product Development at Clearwater Paper, which is introducing new paperboard brands with recycled content in an industry dominated by non-recycled products.

Subjects include product innovation in a traditional industry, holistic thinking, and the social trends that are making sustainable paper cups, containers and packaging the subject of table conversation. This continuing series explores environmental responsibility with sustainability-minded companies.

- North America’s largest non-integrated producer of premium paperboard used in folded cartons and cups and a leading provider of private label tissue

- Headquartered in Spokane, Washington, with manufacturing facilities across the U.S.

- First U.S. manufacturer with a full line of paperboard products certified by the FSC® (Forest Stewardship Council®)

1. Why is most paperboard made with non-recycled pulp?

Traditionally, a balanced blend of softwood and hardwood fiber provided for print quality and converting performance – folding, forming, and cutting – required by cup and carton converters. Today, we have access to premium recycled pulp which has allowed us to create the NuVo® and ReMagine™ brands of paperboard which include post consumer recycled fiber.

2. Can paperboard with post consumer recycled fiber bridge the performance gap?

Our products are already doing it. In March of 2019 we launched NuVo brand cup stock, the first premium cupstock with up to 35% recycled fiber content that is compliant with FDA standards for food contact (Sustana Fiber’s EnviroLife®). Our multi-ply blending technology allows us to maintain strength and stretch performance with higher percentages of post consumer recycled fiber. NuVo runs well on cup forming equipment allowing converters to operate with increased efficiency, and our high definition print surface reduces ink usage by 50%.

Cups made with premium NuVo paperboard meet the growing demand for sustainable everyday products consumers feel good about. Sales volumes have been strong and market acceptance continues to grow as more cup converters trial and commercialize the grade.

3. What other trends are shaping demand for paperboard with recycled content?

Some of this is generational: Millennials and Generation Z are looking for companies to make a larger impact on recovered material from recycling. They want brands to be transparent and tell the world how they are building sustainable products. Many brands have learned that they can meet changing consumer priorities if they embrace and promote sustainable packaging to better fit in a circular economy. One of the most effective changes they can make today is to increase the recycled fiber content percentage which promotes the holistic health of the recycled material market.

4. How is this changing the packaging industry?

Packaging is becoming an impact player in the circular economy where products are made, used, then recycled into valuable new products, closing the loop. People now talk about whether coffee cups are recyclable, or compostable, or recycled, which was not exactly dinner table conversation ten years ago! Sustainability has always been a journey of small steps that add up to make a significant impact toward a better future for generations to come. What I personally like about the circular economy concept is that it is a holistic group of actions we can take that are intuitively understood by consumers.

5. Can you provide an example of a Clearwater Paper customer pursuing sustainability?

Customer: Visstun is a cup converter in the West. They market hi-definition print, fast turnaround and premium cup performance.

The solution: NuVo cupstock with 35% recycled fiber content and our enhanced high definition surface. Our enhanced surface option makes for a vibrant printed image and can reduces ink usage on hot cups by approximately by 50%.

6. Are other market categories ready for paperboard products with recycled content?

The feedback from larger Consumer Packaged Goods brands started coming in after our NuVo launch. Customers desire a premium folding carton paperboard grade with post consumer recycled fiber content.

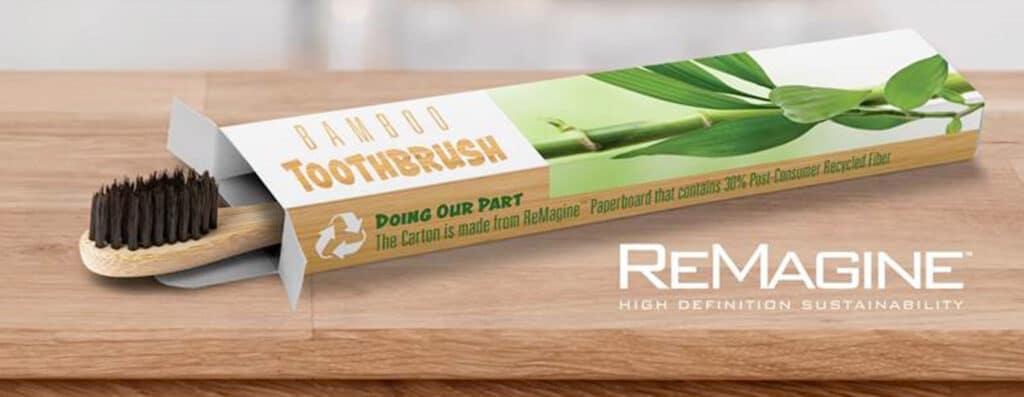

After the success of NuVo cupstock, we trialed, developed, and recently launched a new brand of premium paperboard with recycled fiber content. Our new brand is called ReMagine and it offers high definition sustainability with up to 30% post consumer recycled fiber while maintaining the superior print and converting performance. It represents the first premium white paperboard produced with up to 30% post consumer recycled content. ReMagine meets the highest standards for food safety and cleanliness. ReMagine contains Envirolife post consumer recycled fiber from Sustana Fiber, which is FDA compliant for direct food contact. ReMagine paperboard will convert into branded cartons for retail products like cosmetics, supplements, golf balls and pharmaceuticals where high-quality process printing is critical.

7. Does your ReMagine folding carton brand have the printing and converting performance comparable to non-recycled products?

We designed ReMagine to consistently maintain the superior print and converting performance our customers demand.

8. What’s the difference in the manufacturing process, with non-recycled and recycled fiber?

Clearwater Paper makes premium paperboard from a mix of softwood pulp for strength combined with hardwood pulp that smooths the sheet surface while making it more supple and pliable. We adjust and fine tune the fiber blend mix to provide an optimum balance of strength and performance.

For ReMagine and NuVo, we use premium Envirolife post consumer recycled fiber. We adjust and fine tune the fiber mix to meet strength and performance specs.

9. How is Clearwater Paper unique in the industry?

Clearwater Paper owns one of the few multi-ply paperboard machines in North America, with premium coating capabilities. We use this premium multi-ply paper machine to produce our NuVo brand of cupstock with up to 35% post consumer recycled fiber content.

Clearwater Paper also owns two additional premium paper machines that produce folding carton paperboard products like ReMagine and Candesce®, using our special mix of virgin softwood and up to 30% of post consumer recycled fiber. These machines use a traditional single ply technology.

10. Is paperboard with 100% recycled fiber possible?

That is a great question that we get asked often. It’s all about optimizing performance and recycled content. Premium folded cartons and paper cups requires a paperboard that contains a unique balance of strength, stretch, surface smoothness, and shade. Clearwater Paper is committed to increasing the post consumer recycled fiber content of ReMagine as high as we can while maintaining the performance customers demand. Today our maximum post consumer recycled content is 35% for our NuVo cupstock grade and 30% for our ReMagine folded carton grade.

11. Why have you created innovative solutions to include recycled fiber?

We believe innovative solutions require focused collaboration by all stakeholders in the supply chain and design process. We use a charter score system to prioritize innovation projects and a stage gate material development process. Our new materials with recycled content help our customers approach packaging design from a circular economy point of view. This point of view strives to design out waste and pollution, keep products and materials in use and support the regeneration of natural systems. Consumers are asking brands for sustainable products and packaging, so brands talk about that packaging with converters, and converters talk to us.

The most successful way to optimize sustainable packaging is when the brands, converters, material suppliers and raw material suppliers all work together towards material and design optimization. That is a reason we work with post consumer recycled fiber suppliers, like Sustana Fiber.

12. What led you to use recycled fiber?

In 2018, we toured Sustana Fiber’s Wisconsin facility. The tour allowed us to better understand the multi-step process involved to clean and refine the recycled fiber, which was remarkable. At that point, we could see that the recycled fiber would fit the premium standards for our folding carton grades of paperboard.

While working through our NuVo stage gate in 2018 our trial performance data revealed our multi-ply fiber blending technology allowed us to increase the post consumer recycled fiber content of our cupstock up to 35% and potentially beyond. This blending capability allowed us to place the stronger softwood fiber in the outer layers which supported a higher percentage of post consumer recycled fiber in the center layer.

13. Why is consistency so essential in recycled fiber?

We make premium white paperboard which is held to the highest standards of performance. Consistency is how we gain customer confidence because packaging converters need paperboard to perform consistently all of the time.

14. Do your customers – independent converters – expect innovation?

The independent carton converter is the cornerstone of the retail packaging industry and must innovate and evolve to compete, so they look to us for differentiated solutions. We take the same approach as we understand the value of innovating products to stay relevant with the consumers who are the ultimate customer for everyone in the supply chain. An example of a typical end user customer? A sustainable cosmetics brand that wants recycled fiber in their packaging, in line with their new 2025 sustainability target goals.

We stay closely connected to the customer and the consumer and strive to keep ahead of the trend. And stay nimble enough to commercialize new products quickly. This means building the best product we can and continuously optimizing to make it better.

15. Does Clearwater see themselves as an industry innovator?

I think the answer to that question is tied to how we approach our customers. What is important is if independent packaging converters and brand owners believe we are innovators. I’d say Clearwater Paper has the core values that encourage thoughtful change and collaboration to make an impact and stay connected to our customers.

Listening to the market and understanding the critical trends is key. With sustainable products, you never really have it all figured out because new ideas and materials are constantly being created and improved. You must continuously evolve to survive. Sustainability truly is a journey not a destination. That long journey is how we make the impact.